Introduction:

In a rapidly evolving industrial landscape, innovative solutions are crucial to meet the diverse needs of various industries. Aluminum circle plates have emerged as a versatile material, finding applications in numerous sectors, ranging from automotive and aerospace to electronics and packaging. As businesses seek optimized performance and efficiency, the demand for tailored solutions using customized aluminum circle plates has witnessed a substantial surge.

- Understanding Aluminum Circle Plates:

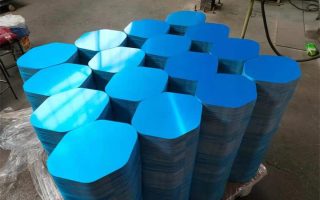

Aluminum circle plates are flat, round-shaped sheets made from high-quality aluminum alloys. Their unique properties make them ideal for a wide range of applications. These plates exhibit exceptional lightweight characteristics, corrosion resistance, and excellent heat conductivity. Moreover, they are highly malleable, enabling complex shaping for specific requirements.

- Tailored Solutions: Meeting Industry-Specific Demands:

The manufacturing industry is witnessing a paradigm shift towards customized solutions to enhance productivity and reduce wastage. By leveraging advanced manufacturing techniques, suppliers are now offering aluminum circle plates tailored to the exact specifications of various industries.

a. Automotive Industry: Customized aluminum circle plates are revolutionizing the automotive sector by offering lightweight solutions for body panels, structural components, and battery enclosures. This leads to improved fuel efficiency, increased range for electric vehicles, and enhanced overall performance.

b. Aerospace Applications: With stringent weight requirements in the aerospace industry, tailored aluminum circle plates are gaining popularity in aircraft manufacturing. Their superior strength-to-weight ratio makes them indispensable for aircraft structural parts, reducing fuel consumption and carbon emissions.

c. Electronics and Electrical Engineering: The electronics sector demands precision in material properties. Customized aluminum circle plates provide exceptional thermal management solutions, ensuring efficient heat dissipation in electronic devices and power systems.

d. Packaging Solutions: The packaging industry benefits from the versatility of customized aluminum circle plates. They are widely used for creating bespoke packaging designs that offer both protection and aesthetic appeal for various consumer products.

- Advanced Manufacturing Techniques:

To deliver tailored solutions, manufacturers are employing cutting-edge technologies like CNC machining, laser cutting, and precision stamping. These techniques allow for intricate designs, tight tolerances, and seamless integration with other components.

- Collaborative Approach: Understanding Client Needs:

To meet the increasing demand for custom aluminum circle plates, suppliers are adopting a collaborative approach with their clients. Through thorough consultation and understanding of specific project requirements, manufacturers can develop aluminum circle plates that perfectly align with the desired outcomes.

- Environmental Benefits:

Customized aluminum circle plates not only offer superior performance but also contribute to sustainability efforts. The inherent recyclability of aluminum and the reduced material wastage in tailored solutions support a greener approach to manufacturing.

Conclusion:

As industries seek optimized solutions to stay competitive, the demand for customized aluminum circle plates continues to grow. Their versatility, lightweight nature, and tailored design options make them the material of choice for meeting specific industry demands. By unlocking the potential of customized aluminum circle plates, businesses can achieve greater efficiency, reduced costs, and sustainable outcomes in their respective domains.